Coatings

| Because the basis of NdFeB is easily oxidized and corroded, we use different kinds of coatings to protect the basis. Generally, we have NiCuNi, Zn, CZn, Epoxy, Phosphating, Teflon, and so on. | ||||

|

|

|

||

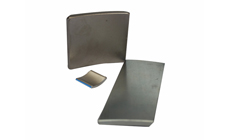

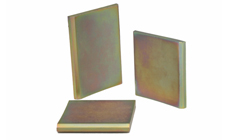

| NdFeB Magnet Coated Ni-Cu-Ni | NdFeB Magnet Coated White Zinc | NdFeB Magnet Coated Color Zinc | ||

| The Nickel-Copper-Nickel(Ni-Cu-Ni) coating has excellent physical and chemical properties, like corrosion resistance, hardness, abrasive resistance. | Blue white zinc coating is generally thinner than the Ni-Cu-Ni coating and anticorrosion ability is relatively good. Blue white zinc coating after | Epoxy resin has good physical and chemical properties, and has excellent adhesion strength on the surface of the metal and nonmetal materials, good | ||

|

|

|

||

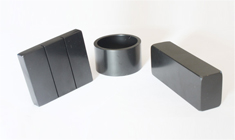

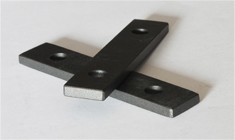

| Magnets coated Epoxy | Phosphated NdFeB Magnet | Magnets coated Teflon | ||

| Epoxy resin has good physical and chemical properties, and has excellent adhesion strength on the surface of the metal and nonmetal materials, good dielectric properties, small | Phosphate coating provide protection to the base metal and prevent the base metal from corroding to some extent and has the characteristics of no coating thickness. Phosphate | Teflon has unique and excellent heat resistance(180~260℃), low temperature (-200℃) resistance and dielectric properties,etc. It has the highest working | ||